Plasma Systems

TPC 2143

Material Geometry

Material Diameter

- 4″ Pipe

Load Capacity

- 15 lbs / ft

Material Length

- Up to 22′

EL-SQRD

Material Geometry

Material Diameter

- Round: 6″ Pipe

- Square/Rectangle: 6″ x 6″

- *Channel: c6 x 13

- Angle: 6″ x 6″

- Flat: 8″

Load Capacity

- 20 lbs / ft

Material Length

- Up to 24′

TPC 2400

Material Geometry

Material Diameter

- Round: 6″ Pipe

- *Square/Rectangle: 6″ x 6″

- *Channel: c6 × 13

- *Angle: 6″ × 6″

- Flat: 8″

Load Capacity

- 20 lbs / ft

Material Length

- Up to 24′

Material Diameter

- Round: 6″ Pipe

- *Square/Rectangle: 6″ x 6″

- *Channel: c6 × 13

- *Angle: 6″ × 6″

- Flat: 8″

Load Capacity

- 30 lbs / ft

Material Length

- Up to 24′

AC-PC

Material Geometry

Material Diameter

- Channel: c12″ × 30″

- Flat: 12″

- Angle: 8″ x 8″

Load Capacity

- 30 lbs / ft

Material Length

- Up to 60′

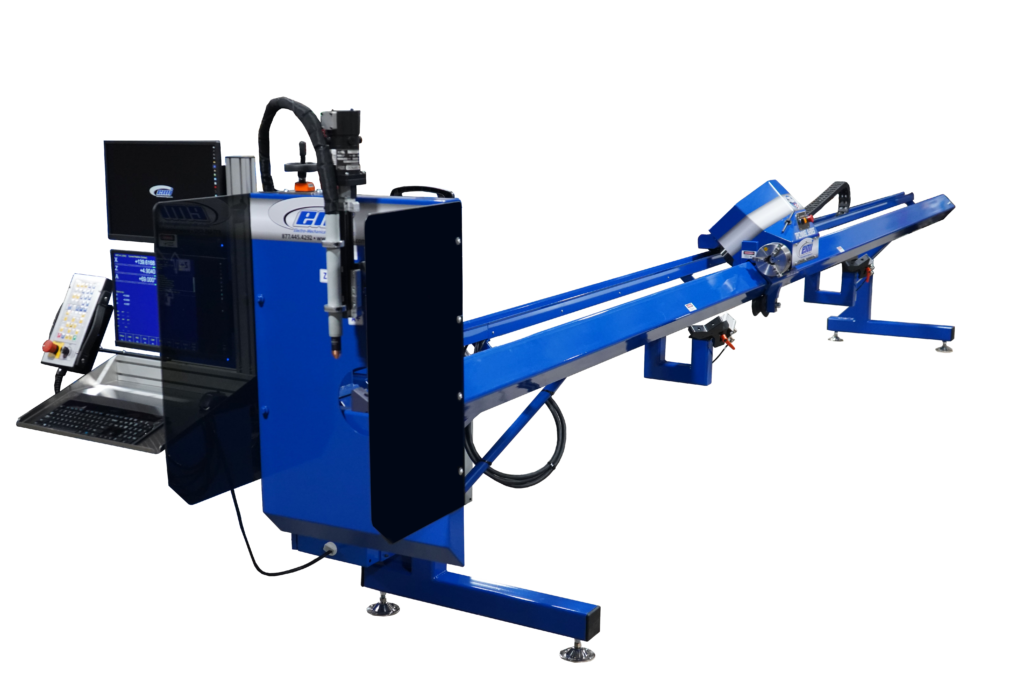

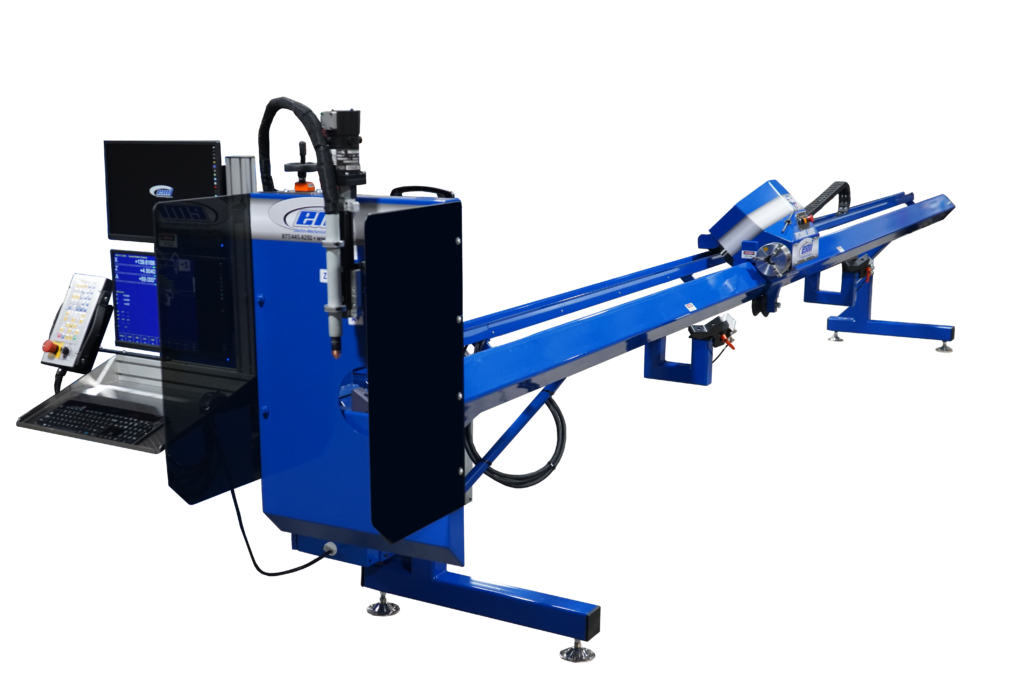

2100 SERIES

PLASMA PIPE CUTTER

Enhance productivity with our 2100 EL. Seamlessly cut round material, streamlining your fabrication process.

In one accurate and efficient process, this plasma pipe cutter and plasma tube notcher cuts, miters and copes, consolidating multiple fabrication steps to save you time and labor. This superior CNC plasma pipe cutter machine is ideal for handrail layout. The 2100 processes up to 4″ diameter pipe/tube.

The 2100 series of machines handle material lengths up to 24ft.

Features:

- Manual loading – to quickly load and process lighter pieces of material

- 2 auto supports – to support and hold material during the loading process

- PieceMaker – EMI’s proprietary, easy-to-use software package

Decrease the amount of time needed for your handrail layout while also simplifying the process your team takes to go from stick to part with the 2100EL Series plasma notcher. With weld ready and accurate handrail parts, taking your fabrication to the next level has never been easier.

Advantages:

- Non-beveling head on machine creates weld ready components, meaning less time grinding for weld prep or finished product.

- Reduce or eliminate manual measuring, sawing, notching, drilling, deburring, and repetitive handling

- Automatic machine programming means that you don’t need to reinvent your workflow to take advantage of the latest automation.

- EMI satisfaction guaranteed 3-year warranty means you can have confidence your machine will keep up with your needs

- Low price point makes this machine accessible to anyone looking to get their foot in the door to see the advantages of a plasma tube notcher.

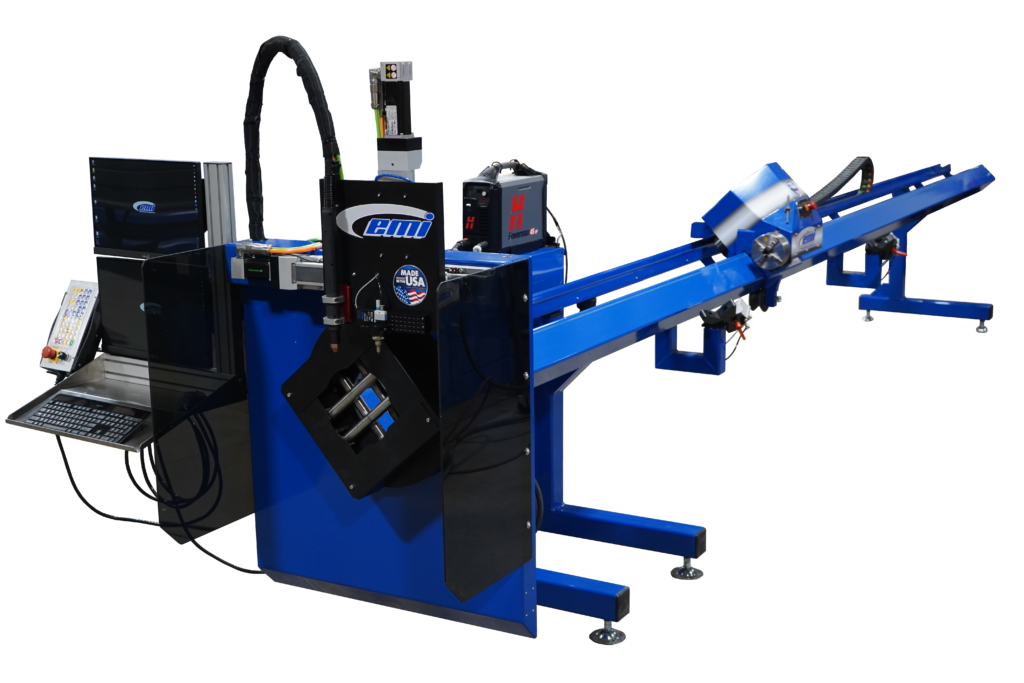

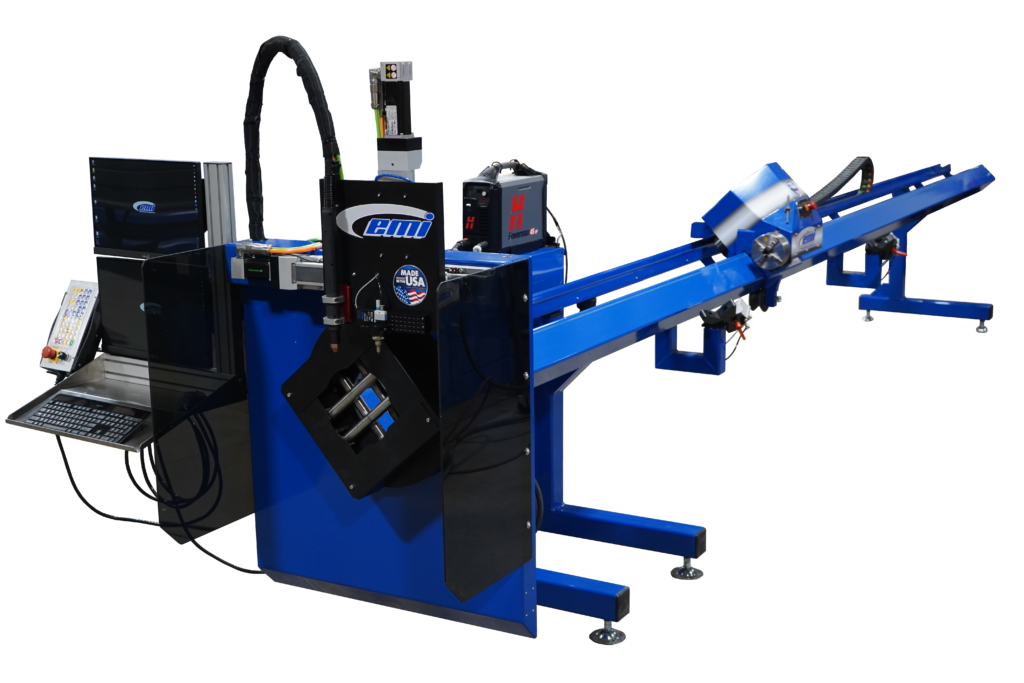

2400 SERIES

TUBE PLASMA CUTTER

Experience Increased Productivity with the TPC 2400 Series: The Autoloading Capability of this CNC Plasma Cutting Machine Increases Capacity and Maximizes Efficiency.

Optimize your operations with one of our TPC2400 series machines, featuring an advanced material indexing system, it effortlessly loads full lengths of round, square, and angle iron. This machine works great in a shop that normally processes large structural members or big multi-stick batches of similar materials. Expand your plasma cutting processing capabilities to increase manufacturing and fabrication.

The 2444 model can handle material lengths up to 20/lbs ft.

The 2464 model can handle material lengths up to 30/lbs ft.

Features:

Discover unmatched efficiency of autoloading and optimize your operations. Designed for processing large structural members and big multi-stick batches, this CNC plasma tube cutter simplifies processes and effortlessly handles various materials with precision.

Advantages:

- Automated material handling decreases the risk of injury to your operators, allowing you to send your big work to the floor without worry.

- The machine’s non-beveling head creates weld-ready components, meaning less time is required grinding for weld prep or the finished product.

- The speed and efficiency of the TPC2400 series provides an excellent alternative to a laser cutter for customers who need the capacity but can live with a little less precision.

- EMI satisfaction guaranteed 3-year warranty means you can have confidence your machine will keep up with your needs.

Angle-Channel Processing Center

AC-PC

Maximize Your Capabilities by Eliminating Time for Stair Layout and Improving Piece Rates Processing Angle Iron and Flat Bar.

The Angle-Channel Processing Center cuts and marks angle iron, C channel, and flat stock. With a state-of-the-art alignment system and 60’ capacity, this CNC plasma cutting machine is great for a shop looking to increase stair stringer capacity, replace an old angle line with a more versatile piece of equipment, or offload small work from their beam line or coper.

The AC-PC handles material lengths up to 60’.

Features:

- Automated Setup Laser – Reduce material changeover and increase accuracy and consistency.

- Powermax 45ASYNC – Plasma marking system simplifies stair stringer layout and part marking.

- Pass Through Auto-vice – Allows for processing of 60’ material on a 27’ footprint.

Manufacturing steel stair stringers according to metal staircase design is made fast and exact – this plasma cutter cuts, draws stair layout lines, and burns holes in one smooth operation. Incorporating angle and channel cutting capabilities, the AC-PC can simultaneously cut and burn bolt holes for angle clips, function as a pipe angle cutter, and deploy many other features and functions.

Advantages:

- Cut any combination of material sizes and profiles with no tooling changes reduces the knowledge required for operators to have success with the machine.

- Reduce or eliminate manual measuring, sawing, notching, drilling, deburring, and repetitive handling.

- Optimized stair stringer layout saves time by automating the process, allowing welders to focus on welding rather than layout.

- Offloading smaller structural and other miscellaneous work that is costing you time on your beam line or robotic coper allows you to keep that work in-house.

- EMI satisfaction guaranteed 3-year warranty means you can have confidence your machine will keep up with your needs.

EL-SQRD

TUBE PLASMA CUTTER

Our EL-SQRD Multi-Profile Machine Combines Multiple Tedious Fabrication Steps into One Accurate and Efficient Operation.

The EL-SQRD is a CNC Plasma Cutting Machine that processes round, square, rectangle, angle, channel, and flat stock. It is perfect for those who want the advantages of the TPC 2100 plasma cutting machine but who want to expand their material profile capabilities.

The EL-SQRD handles material lengths up to 24ft.

Features:

- Torch breakaway – to prevent costly downtime and repair.

- Self-centering front support – for easy material changeover

- PieceMaker – EMI’s proprietary, easy-to-use software package

In one accurate process, you can miter cut or cope, burn holes and slots in multiple different profiles. Reduce or eliminate manual measuring, sawing, notching, drilling, and repetitive handling.

Advantages:

- Cut any combination of diameters and intersection angles with no tooling changes.

- Reduce or eliminate manual measuring, sawing, notching, drilling, deburring, and repetitive handling.

- Produce weld-ready miters and copes and significantly improve weld penetration.

- Simultaneously produces holes, slots, and other features without drilling or punching.

- Decrease handrail layout time by eliminating fitting hassles caused by material warping from heat, in part due to EMI’s closed-loop servo motor system